Multimedia console

Multimedia Console as a Touchless Operating Panel – Use Case at “WPRA”

This project showcases the flexibility of the GETT.PROJECTS modular approach, demonstrated through a custom solution developed for a client we refer to as “We Prefer to Remain Anonymous” (WPRA).

As an OEM service provider, confidentiality is often part of our agreements. Many of our clients request project-level privacy and prefer not to be named in marketing communications. The term WPRA is fictional and stands for “We Prefer to Remain Anonymous.”

DESCRIPTION OF THE PROJECT

Client: WPRA

Type of product: multimedia console

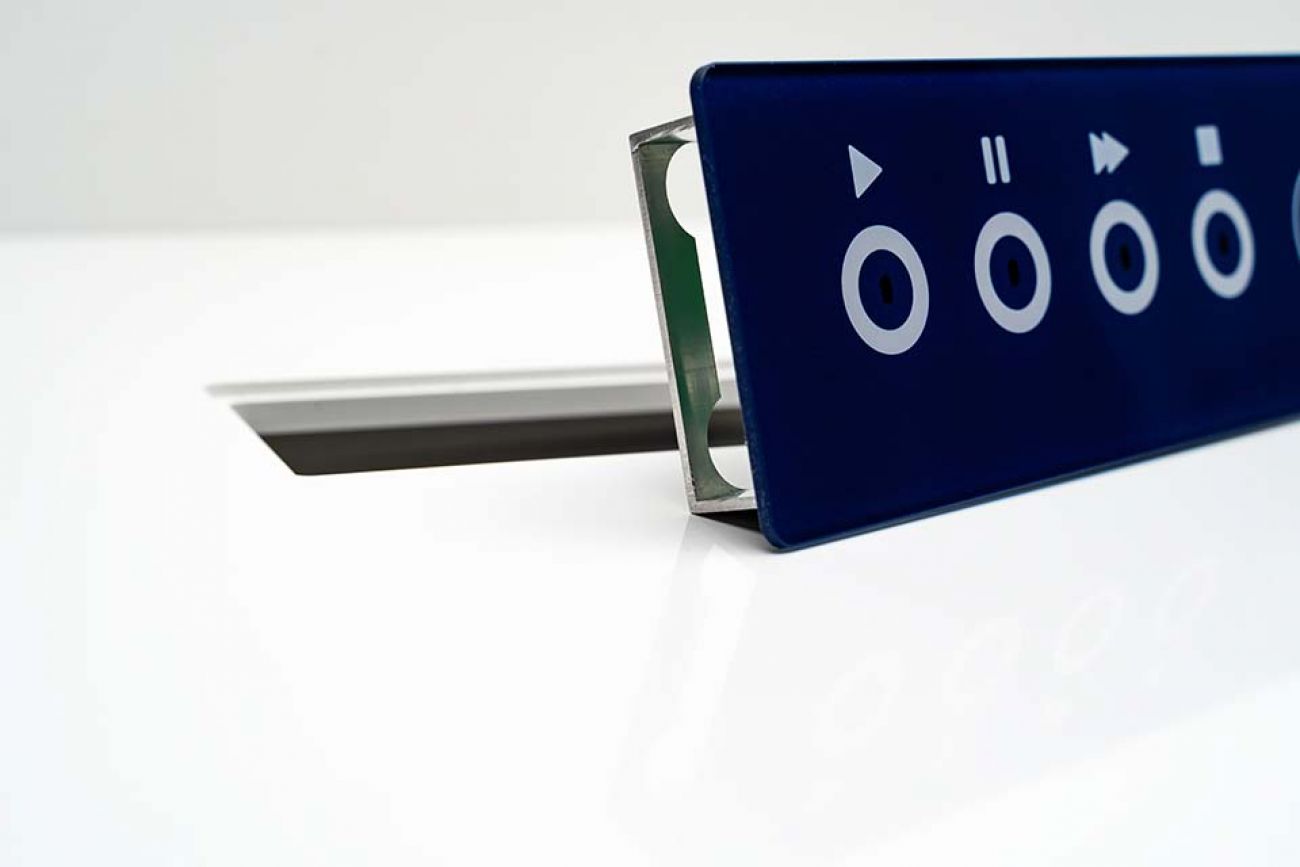

The multimedia panel was developed as a modern, intelligent, and visually appealing interface featuring six keys, an NFC reader, and a display — all within a modular design concept.

Beyond registering keystrokes and displaying content, the panel is also engineered to detect specific installation configurations and generate switching signals. Additionally, it supports the integration of complete menu navigation as well as control and processing logic, enabling flexible and application-specific functionality.

The WPRA* client operates within the food industry. However, thanks to its design-forward features, the multimedia console is also ideally suited for use in visually demanding environments — such as point-of-sale settings, interior design applications, or the furniture industry.

Due to the timing of the project during the COVID-19 pandemic, innovative touchless input technology with optical buttons was the preferred solution — offering enhanced hygiene and user safety.

GETT.CONSULTING

Project Kickoff and Concept Development

- Familiarization with the intended application and surrounding conditions

- On-site analysis of the previous model in use

- Evaluation of customer-specific requirements

- Development of multiple technical concepts for presentation, including solutions based on:

- Capacitive touch technology

- Optical sensor technology

- Membrane keypad technology

Concept Selection and Specification Phase

- Presentation and discussion of all proposed concepts

- Explanation of the pros and cons of each option, including initial cost estimates

- Customer decision in favor of one concept, followed by definition of additional requirements

Selected Concept:

- Glass-based operating panel

- Illuminated optical buttons

- Integrated display for visual feedback

- Modular design, adaptable to specific installation scenarios

- Custom graphical icons specified for the display

Next Steps:

- Finalization of the concept

- Creation of a detailed specification sheet to guide development and production

Finalization and Handover

- Presentation of the finalized concept along with a binding quotation

- Signing of the agreed specification sheet by all parties

- Official project handover to GETT.LAB for development and implementation

GETT.LAB

Materials, Assembly, and Tools

- Components: Glass surface, mounting frame, assembly parts, and additional hardware

- Processes: Assembly and installation of all mechanical elements

- Tools & Technologies: SolidWorks for 3D design; 3D printing used for prototyping and fit testing

Glass Print Layout and Prototyping

- Task: Creation of the print layout for the glass surface

- Tools Used: CorelDRAW for graphic design; digital glass printing for prototyping purposes

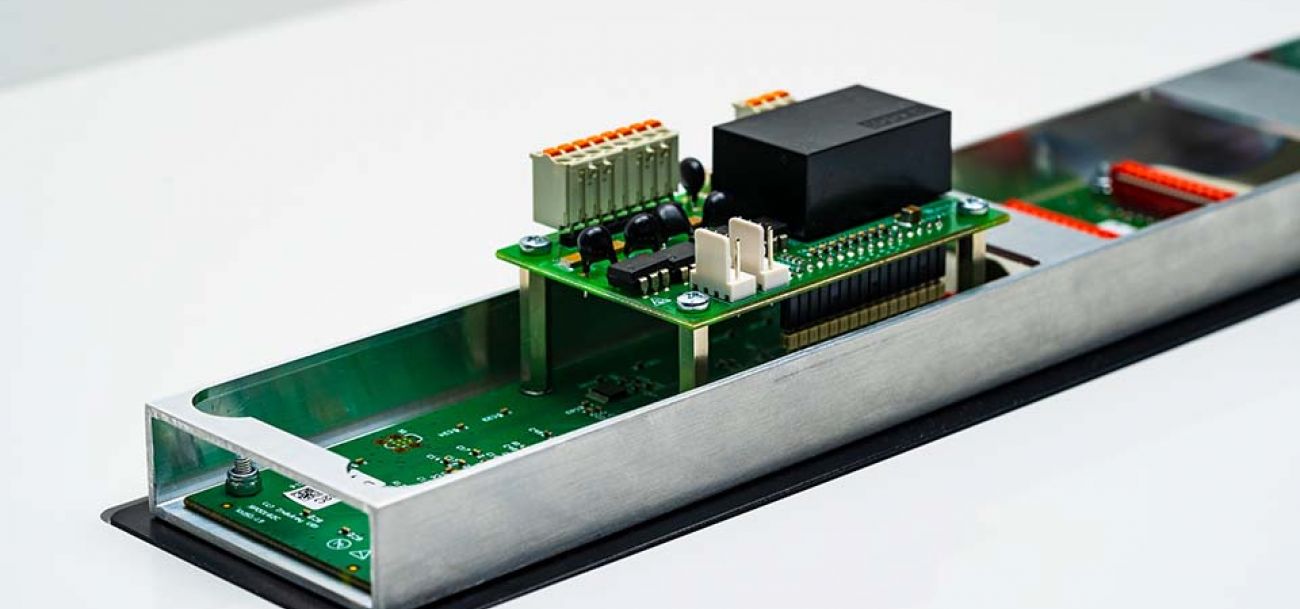

Electronics Development and Prototyping

- Tasks:

- Designing the circuit layout

- Routing and commissioning the power supply unit

- Developing the key circuit board and adapter components

- Tools Used:

- Altium Designer for PCB layout

- Comprehensive lab equipment for prototyping and functional testing

Input Evaluation and Output Control

- Scope of Work:

- Testing and validation of keys and interface functionality

- Verification of display content accuracy

- Implementation of logic to control output based on specific input conditions

- Tools Used:

- C compiler for STM32 microcontrollers

Testing and Calibration

- Tasks:

- Definition of test parameters and scope for both semi-finished and final products

- Specification and execution of key calibration procedures

- Tools Used:

- Dedicated calibration tool

GETT.QUALITY

Test Scope and Procedures

What Was Tested:

- Adhesion of the printed color to the glass

- Durability of the printed surface

- Print quality and visual integrity

- Strength and longevity of the bonding

- Long-term reliability of electronic components

- Performance under varying environmental conditions (climatic testing)

Tools & Methods Used:

- Refrigerator for cold storage simulation

- Climatic shock testing cabinet

- Spectral photometer for color and image quality evaluation

- Cross-cut adhesion test according to DIN EN ISO 16276-2

GETT.FACTORY

- Manufacturing the retaining frame from one aluminum section

- Printing the glass front using the screen printing process.

- Bonding the glass to the frame

- Installing electronic components, including diffusers and light blockers

- Inserting and securing all electronic assemblies into the housing

Final Functional and Visual Inspection

- Tasks:

- Comprehensive testing of all functions

- Verification of optical quality and visual finish

- Tools Used:

- Calibration tool

- Various precision measuring instruments

Testing and Calibration

- Tasks:

- Definition of test parameters and scope for both semi-finished and final products

- Specification and execution of key calibration procedures

- Tools Used:

- Dedicated calibration tool

Our all-round carefree package

Where else can we support you beyond consulting?

We offer a fully customized service package tailored to your needs. Our experts guide you through every stage - from the initial consultation and development to networking and the final production of your product. You also have the flexibility to select individual service packages based on your specific requirements.